Today we received an inquiry about 500kg mounted jib crane from a Zambian customer as follows:

Dear Sales,

Please urgently provide us with a quotation for a manually operated beam mounted 500kg jib crane with the following specifications;

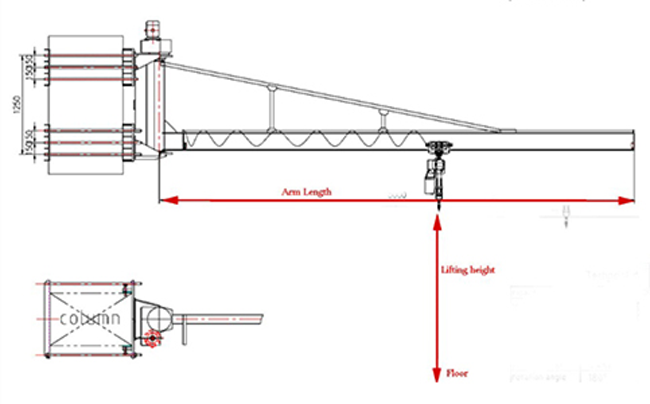

1. Lifting height = 4 meters

2. Radius = 180 deg

3. Power supply = 380/400V

4. Arm length = 3 metres

5. Mounting = Beam mounted

Wall Mounted Jibs: This jib crane is available in two models—a wall bracketed jib and cantilevered jib. Use an enclosed system for small capacities and a steel beamed structure for larger capacities. Wall Mounted Jib Cranes provide excellent coverage in circular areas not efficiently served by a main crane. They’re ideal for supporting tool balancers, air balancers, hoists, vacuum lifters and welding wire feeders.

Wall Jib Crane Wall Mounted 500kg Jib Crane Price

The wall-mounted jib crane is a special lifting device designed according to user needs. It has the advantages of novel structure, rationality, simplicity, convenient operation, flexible rotation, light weight, and flexible load movement. It is an energy-saving and efficient material lifting equipment. It can be widely used in factories, mines, workshop production lines, assembly lines and machine tool loading and unloading, as well as heavy lifting in warehouses, docks and other occasions.

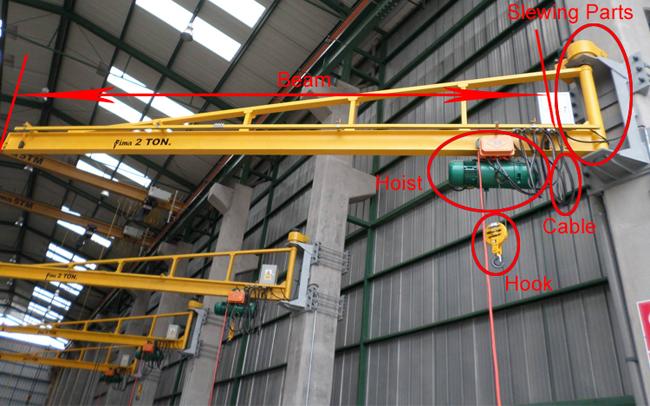

The wall-mounted jib crane (wall crane) is composed of a bracket, a jib device and an electric chain hoist. The cantilever is fixed on the wall or concrete column, and can be rotated according to user needs. The rotary part is divided into manual rotary and electric rotary. The electric chain hoist is installed on the cantilever track for lifting heavy objects.

Structure and Operation of 500kg mounted jib crane

This machine is mainly composed of 1. Cantilever; 2. Rotary device; 3. Electric chain hoist.

The electric chain hoist has the functions of lifting and reciprocating operation on the beam.

The cantilever beam can be driven by the reducer on the slewing device to rotate the rollers.

For the electrical part, see the attached picture: Electrical Principles and Electrical Wiring Diagram. The electrical control box is installed on the chain hoist.

The operation of the machine is realized through the flashlight door button. The flashlight door has eight buttons, which respectively control the fast rising, fast falling, slow rising, slow falling, left and right rotation and the horizontal front and rear travel of the hoist trolley.

Notice:

1. Do not press the speed button and the anti-rotation button of the same motor at the same time during operation.

2. When working, no one is allowed to stand under the boom.

3. It is forbidden to drag heavy objects.

4. Prohibition of overload lifting

No Responses