Dongqi Electric Hoist for Sale

What is a hoist? A hoist is a lifting equipment, designed to lift, move and lower loads easily, simply and safely. Typically, the hoists use wire rope or chain to lift materials. There are different types of hoists, namely, manual or electric, base mounted, or pendant cranes. Lifting hoists can be applied in various conditions and have different moving ways, which should be selected according to your applications.ND type European-spec Electric Hoist

European-spec Electric Hoist

- Product model: ND, NR

- Lifting capacity: monorail type up to 20 tons, electric hoist crab type up to 80 tons

- Lifting height: 6-50 meters

- Working class: M5, M6

- Power supply: 220-480VAC 50/60Hz 3Phase

- Ambient temperature: -20-40℃

CD1 Single Speed Wire Rope Electric Hoist

CD1 Single Speed Electric Hoist

- Product model: CD1

- Lifting capacity: monorail type up to 20 tons, electric hoist crab type up to 32 tons

- Lifting height: 6-50 meters

- Working class: M3, M4

- Power supply: 220-480VAC 50/60Hz 3Phase

- Ambient temperature: -20-40℃

MD1 Double Speed Electric Hoist

Double speed electric hoist is a small-sized lifting equipment, which is installed on the single girder, bridge cranes, gantry cranes, jib cranes for material handling. As one of the commonly used material handling equipment, the double speed electric hoist is usually used in factory, mining, railway, port, and storage, etc.

MD1 Double Speed Electric Hoist

- Product model: MD1

- Lifting capacity: monorail type up to 20 tons, electric hoist crab type up to 32 tons

- Lifting height: 6-50 meters

- Working class: M3, M4

- Power supply: 220-480VAC 50/60Hz 3Phase

- Ambient temperature: -20-40℃

Advantages of Double Speed Electric Hoist

Double speed electric hoist of DQCRANES has the following advantages:- The double speed electric hoist is designed with compact structure, with the features of small size, light weight, standardized parts, etc.

- The double speed electric hoist has fast and slow lifting speed, which can make the lifting stable and easy.

- The double speed electric hoist has big lifting capacity, high working efficiency, and long working life.

- The double speed electric hoist is easy to operation and convenient to repair.

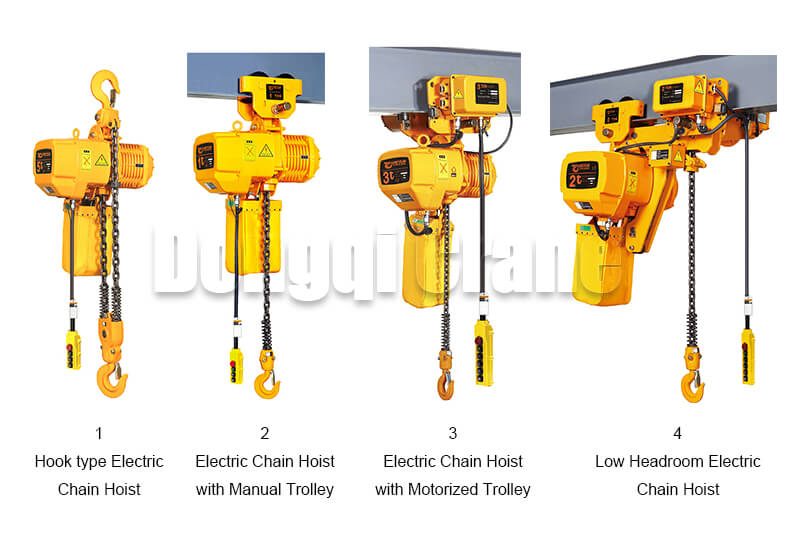

Electric Chain Hoist

Electric chain hoist is a light and small lifting equipment for material handling. Electric chain hoist is mainly consisted of motor, transmission mechanism and chain wheel, etc. Electric chain hoists from DQCRANES have the features of beautiful outlook, solid durability, and international technology, etc. The inside gears of electric chain hoist are hot quenched which increases the wear resistance of the gear and toughness.

Electric Chain Hoist Types Dongqi Crane Supply: hook type electric chain hoist, electric chain hoist with manual trolley, electric chain hoist with motorized trolley, low headroom electric chain hoist

- Product model: WBH, HHBB

- Lifting capacity: 0.5-35 tons

- Lifting height: 3-50 meters

- Working class: M3, M4

- Power supply: 220-480VAC 50/60Hz 3Phase

- Ambient temperature: -20-40℃

Metallurgical Electric Hoist

Metallurgical electric hoist introduction is a type of material handling equipment, especially designed for the application in metallurgy environment for handling molten metal, etc. Metallurgical electric hoist is equipped with dual brake, double spacing, insulation boards, and other protections, with the working class of M3. The lifting capacity of metallurgical electric hoist is 1 to 20 tons and the working class is M3 and M4. The main parameters of metallurgical electric hoist are presented as follow:- Product model: YH

- Lifting capacity: 1-20 tons

- Lifting height: 3-18 meters

- Working class: M3, M4

- Power supply: 220-480VAC 50/60Hz 3Phase

- Ambient temperature: -20-60℃

BCD Explosion-proof Electric Hoist

Explosion proof electric hoist is a specially designed material handling equipment with the features of explosion proof. Explosion proof electric hoist is designed and manufactured according to GB3836-2000 provisions and international regulations, with the explosion proof mark of D II BT4, and D II CT4, which can be supplied to applications that has the level of II A, II B, II C grade, the temperature sub-groups T1-T4 group of combustible gas, steam and air from the explosion gas mixtures in a zone, zone 2 areas.

BCD Explosion-proof Electric Hoist

- Product model: BCD

- Lifting capacity: 1-16 tons

- Lifting height: 3-18 meters

- Working class: M3, M4

- Power supply: 220-480VAC 50/60Hz 3Phase

- Ambient temperature: -20-40℃

Applications of Explosion-proof Electric Hoist

Explosion proof electric hoist can be used on the main I-beam track to run in straight or curve line to handle materials or installed on a fixed bracket as a lifting solution for heavy loads. Explosion- proof electric hoist also can be fixed to different applications, working with explosion proof single girder overhead travelling crane or with the explosion proof dual beam bridge crane, etc.Environmental Conditions of Explosion-proof Electric Hoist

Explosion proof electric hoist is applied to the environment with the elevation below 1000m, with relative humility, with the Class I, Class IIB and IIC. The temperature scale of explosion proof hoist is class T1-T4 (explosion hazardous area). Explosion-proof electric hoist can be hanged on I beam rail, explosion proof single girder or double girder, or other fixed support for material handling, etc.Electric Winch

Electric Winch

Electric Hoist Operation Safety Lists

- Do not exceed the safe load limit of hoist.

- Maintain hoist ropes and chains lubricated.

- Hoist loads up from right over the loads or it may swing when lifting if not centered.

- Place hoists in the highest part of hook area to make sure hook support is in line with hook shank directly.

- Lever operated hoist can be pulled in any direction in a straight line. However, side pulling or lifting increase wear and stress on hoist parts. Pushing a loaded hoist is safer (A). If it must be pulled, use a rope (B).

- To load the lower hook, place loads right in line with the hook shank to make sure load chain in a straight line from hook shank to hook shank.

- Stand clear of load completely.

- Place loads in the hook completely.

- Move hoist controls smoothly to avoid abrupt and jerky movements of loads.

- Make sure the sling and hoisting ropes from slacking before lifting.

- Keep the loads from any loose material, parts, blocking and packing before lifting.

- Make sure all people away from loads before lifting.

No Responses