1 ton jib crane for sale Qatar for material handling in infrastructure construction.

Client background:

The client is a local technical service engineering company in Qatar. They help their clients and customer to build factories, workshops and other facilities, mainly engaging in infrastructure projects.

Crane products purchased by Qatar customers:

BZ 1T pillar jib crane, the lifting height is 3 meters and the effective arm length is 5 meters.

Technical parameter confirmation stage:

The Qatar customer inquired about the jib crane price around November 2018 and said that they would come to the factory to inspect the finished pillar jib crane.

In the process of determining the order, there is a lot of discussion on technical parameters, such as the power of the rotating motor, the diameter of the cantilever base, and the thickness of the column. Always communicate with their engineers.

1ton Jib Crane Using environment:

Can you consider hoist rope length to 15 meters because this unit will be mounted near to pit.

Also please confirm the unit is for outdoor application near sea and outside temperature is 50degc and 95%o humidity.

Technical tips:

It is used for seaside, the temperature is 50 ℃, the humidity is 95%, so it is required to spray special epoxy corrosion paint.

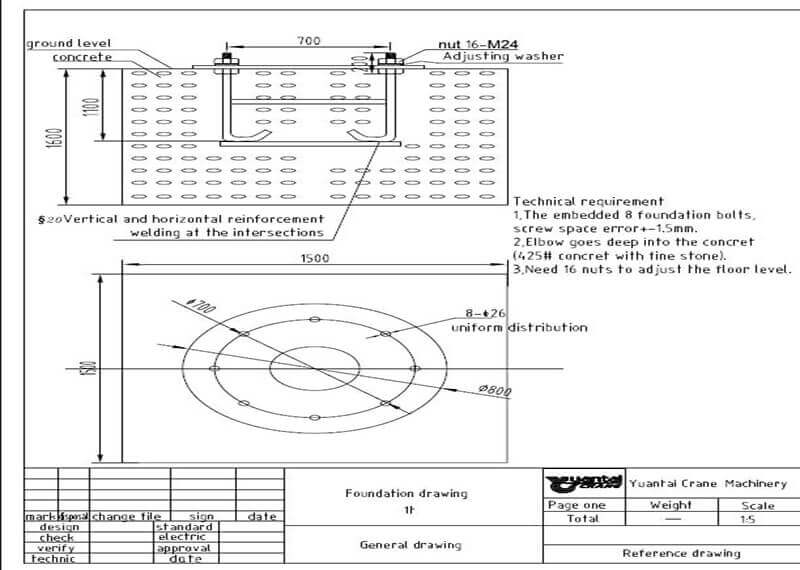

On the foundation of jib cranes

Jib cranes are lightweight crane systems usually featured in factory production lines and similar lightweight lifting applications. Regular jib crane systems feature safe working loads up to 5000kg (5T) however more advanced custom-built systems can be adapted to larger capacities.

1 Ton Jib Crane Design and Components

For the most part, jib systems have a very basic design and construction. Compared to workstation cranes and bridge or gantry cranes, they’re simple to operate, and require less maintenance because they have less parts that could potentially breakdown or fail.

Below are some of the components and terms you’ll see mentioned throughout this article:

- Reach/Boom – the horizontal beam that the trolley travels back and forth on.

- Mast/Pillar – the vertical beam used to support the boom on freestanding and mast systems

- Movable Hoist – the hoist is used to lift, position, and lower a load.

- Trolley – the motion of the trolley can be manual, motorized, or pneumatic. The trolley carries the hoist, wire rope or chain, and the hook along the entire length of the boom.

- Rotation – on free standing and mast type jib cranes, you can achieve 360° of boom rotation. On wall and column-mounted jib cranes, you can achieve 180-200° of rotation.

- Electrification/Pneumatic Power – electric collector rings or pneumatic air lines can be added to the top or bottom of the mast to provide rotation assistance and allow for continuous 360° boom rotation.

- Controls – on motorized or air-powered jib systems, you can use a push button controller to control the rotation of the boom, as well as the motion of the trolley and the lifting and lowering motion of the hoist. Multi-speed or variable speed controls are available for the hoist and trolley.

- Hook Height – How high can you or do you want to go with your lifts? You’ll need to know the lowest overhead obstruction to know how tall your jib crane can be.

- Rotation Stop – if the crane is located close to a wall or other obstruction, a rotation stop will limit the crane’s motion before it collides with a nearby object.

- Environmental Considerations – the components of the jib system can be galvanized to resist corrosion for outdoor applications. Also, special control enclosures can be designed for explosion proof applications, and other environments where heat, dust and dirt, or moisture may be a factor.

How to buy a jib crane?

Jib cranes are an economical solution for moving materials within individual work areas or from one work area to another. They can also serve as auxiliary lifting devices under overhead cranes. There are a variety of jib cranes on the market today, with styles ranging from entirely self-supporting to ceiling/bridge or wall-mounted.

When selecting a jib crane that matches your individual requirements, it’s important to think about your operation type, facility structure, cost of the unit and installation, and any necessary options, like motorized rotation, box track festooning, boom locks, and rotation stops.

More specifically, the following factors should be considered when choosing the right jib crane for your specific application:

- Capacity: The maximum weight of the application should never exceed the rated capacity/design weight. The capacity rating is based on a design load that includes the capacity rating of the crane plus 15 percent of the capacity for the weight of the hoist and trolley and 25 percent of the capacity to allow for additional impact. The deflection is based on a design load that includes the capacity plus 15 percent of the capacity for the hoist and trolley. Ensure your manufacturer is using design criteria that allows the least amount of deflection so as not to hamper the performance of the crane.

- Height Under Boom (HUB): The distance from the floor to the underside of the boom. It’s important to consider the size of the hoist and the amount of lifting distance when deciding on your HUB.

- Overall Height: The height to the highest point on the crane after installation. Any attachments, such as electrical entry, should also be considered to provide full rotational potential and freedom from overhead obstructions.

- Working Span: Distance the hoist trolley can travel along the jib crane’s boom. Also factor in the size of the hoist and the required trolley travel distance. The working distance or hook distance extends from approximately one-half the trolley length from the end of the beam to one-half the trolley length from the head assembly or vertical support member of the jib.

- Boom Rotation: Freestanding and mast-type jib cranes can provide 360-degree rotation. Wall-mounted jibs offer 200-degree rotation, and articulating jibs provide 360-degree rotation on the inner and outer arm (freestanding and ceiling-mounted) and 360-degree rotation on the outer arm and 200-degree rotation on the inner arm (wall-mounted).

- Power Requirement: How much power is necessary? Is power required for rotation, trolley, hoist, or all three? (Standard powered jib rotation is approximately 1/2 R.P.M). How will the power be supplied? Bottom or top entry? Electric or air?

- Weatherization: Does the system or its electrical components need to be weatherized for outdoor use?

- Installation: Can the crane be assembled easily to reduce cost? The location will also dictate the type of crane to be selected to insure proper installation. Freestanding jibs require reinforced concrete foundations which can cost more than the crane itself.

Because they are self-supporting, freestanding jib cranes are well suited for outdoor use and can be fully weatherized.

No Responses